Stainless steel is an alloy favored for its durability, efficiency, and versatility. It can be used in various applications, from kitchenware to industrial equipment. One of the more popular types is 18/10 stainless steel, and the second is 304 stainless steel. While both are classified as austenitic stainless steels and share similar properties, they have some distinct differences. In this blog post, we will explore the differences between 18/10 stainless steel and 304 stainless steel.

What is 18/10 stainless steel?

18/10 stainless steel is a type of austenitic stainless steel commonly used in producing cookware, flatware, and other household items. The term "18/10" refers to the steel composition, which contains 18% chromium and 10% nickel. This gives 18/10 stainless steel excellent corrosion resistance and a lustrous appearance. Compared to other types of stainless steel, 18/10 is considered a high-quality material that is resistant to rust and tarnishing, easy to clean, and safe for use with food.

18/10 stainless steel is very durable and boasts excellent properties that make it very useful in various applications. It's popular in kitchenware, cutlery, and medical equipment like implants, and surgical instruments.

What is 304 stainless steel?

304 stainless steel is a type of austenitic steel that contains 18% chromium and 8% nickel, and small amounts of other elements. 304 stainless steel has excellent corrosion resistance as well as the strength to last plenty of wear & tear. 304 stainless steel is popular for a number of reasons. It is resistant to corrosion and easy to clean, making it a good choice for home appliances, car parts, industrial equipment, and architectural components. 304 stainless steel is a versatile metal that can be used in various manufacturing processes. There are also various form of 304 stainless steel, such as plates, wires, tubes, bars, etc. 304 stainless steel is a high-quality material widely used in many industries and applications. It has excellent properties and reliability.

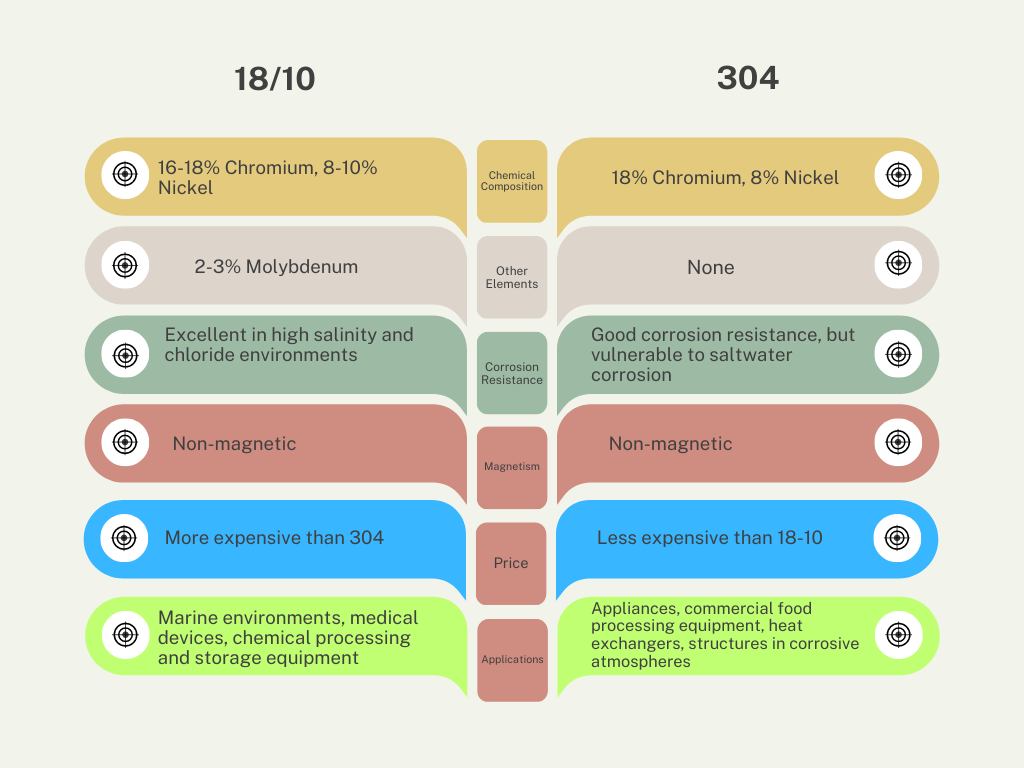

Differences between 18/10 Stainless Steel and 304 Stainless Steel:

| Criteria | 18-10 Stainless Steel |

304 Stainless Steel

|

| Chemical Composition | 16-18% Chromium, 8-10% Nickel |

18% Chromium, 8% Nickel

|

| Other Elements | 2-3% Molybdenum | None |

| Corrosion Resistance | Excellent in high salinity and chloride environments |

Good corrosion resistance, but vulnerable to saltwater corrosion

|

| Magnetism | Non-magnetic | Non-magnetic |

| Price | More expensive than 304 |

Less expensive than 18-10

|

| Applications | Marine environments, medical devices, chemical processing and storage equipment |

Appliances, commercial food processing equipment, heat exchangers, structures in corrosive atmospheres

|

Difference in Chemical Composition

304 stainless steel

| Standard | AISI (UNS) | C, ≤ | Si, ≤ | Mn, ≤ | P, ≤ | S, ≤ | Cr | Ni |

| ASTM A276/A276M | 304 (S30400) | 0.08 | 1 | 2 | 0.045 | 0.03 | 18.0-20.0 | 8.0-11.0 |

18/10 stainless steel

| Element | Minimum (%) | Maximum (%) |

| Carbon | 0.08 | 0.2 |

| Manganese | 2 | - |

| Phosphorus | 0.045 | - |

| Sulfur | 0.03 | - |

| Silicon | 1 | - |

| Chromium | 17 | 20 |

| Nickel | 8 | 10.5 |

| Nitrogen | - | 0.1 |

Difference in application:

Both 304 stainless steel and 18/10 stainless steel are commonly used in kitchenware, cutlery, and other household items due to their resistance to corrosion, durability, and overall aesthetic appeal. However, there are some differences between the two materials.

304 is highly resistant to corrosion, heat, and chemicals, making it a popular choice for industrial and food processing applications. It is also commonly used in kitchenware such as sinks, cookware, and appliances because of its durability, ease of cleaning, and resistance to stains and scratches.

18/10 stainless steel, on the other hand, is a type of stainless steel that contains 18% chromium and 10% nickel. It is also highly resistant to corrosion and is commonly used in kitchenware, cutlery, and other household items because of its bright and shiny appearance. The higher nickel content in 18/10 stainless steel makes it more expensive than 304 stainless steel, but it is often considered a higher-quality material.

In terms of application, 304 stainless steel is typically used in more heavy-duty industrial and commercial applications, while 18/10 stainless steel is commonly used in household items like cutlery, flatware, and serving utensils. However, both materials can be used in a variety of applications depending on their specific properties and requirements.

Factors to consider when choosing between 18/10 stainless steel and 304 stainless steel:

Corrosion resistance:

18/10 and 304 steel exhibit similar corrosion resistance; however, 18/10 is more corrosion-resistant due to its higher nickel and chromium content.

If the item is likely exposed to high levels of corrosive substances, choose 18/10 stainless steel.

Cost:

304 stainless steel is less expensive than 18/10 stainless steel because it has less nickel content. The higher cost of 18/10 stainless steel could make it a more economical choice in some cases.

Machinability:

Both 18/10 and 304 stainless steel can be hard to work with, but 304 stainless steel is slightly easier due to its lower nickel content.

Application: When choosing between 18/10 and 304 stainless steel, it is good to consider the intended use. For example, suppose the item will be used in a food industry environment. In that case, 18/10 stainless steel is a better choice because of its superior corrosion resistance and overall safety for use with food.

There are a number of factors that contribute to the choice between 18/10 and 304 stainless steel. It is important to consider all the features before deciding on what type of metal to use.

Tips for maintaining stainless steel:

Regular cleaning:

Stainless steel is a highly useful material with many benefits, but it needs to be cleaned regularly to avoid becoming dull or corroded. Just use a soft cloth or sponge and mild soap to clean the surface, then rinse with clean water and dry up with a soft cloth.

Avoid abrasive cleaners: Avoid using steel wool or abrasive chemicals to clean your stainless steel surfaces, as they may scratch the surface.

Avoid chlorine bleach: Chlorine bleach can be dangerous on stainless steel, so it is important to be careful when cleaning or sanitizing the surfaces.

Directional cleaning: When cleaning stainless steel surfaces, it's best to clean in the direction of the grain (if visible) to avoid leaving scratches or streaks.

Avoid contact with other metals: You should avoid placing stainless steel items in contact with other metals, such as aluminum or copper because they can corrode and cause damage.

Dry thoroughly: After cleaning, be sure to dry stainless steel thoroughly to prevent water spots or corrosion.

Use specialized cleaners for tough stains: For stubborn stains or discoloration on stainless steel, there are specialized cleaners available that can help remove them without damaging the surface. Look for products specifically designed for stainless steel.

By following these tips, you can help maintain the appearance and integrity of your stainless steel items for years to come.

Conclusion:

Both 18/10 stainless steel and 304 stainless steel have their own unique properties and applications. When choosing between the two, it's important to consider factors such as corrosion resistance, magnetism, and price. By understanding the differences between these two types of stainless steel, you can make an informed decision about which one is right for your needs. Regardless of which type you choose, proper maintenance is key to ensuring your stainless steel stays in top condition for years to come.

"GOVERNMENT RECOGNISED STAR EXPORT HOUSE"

"GOVERNMENT RECOGNISED STAR EXPORT HOUSE"

India

India Japan

Japan Russia

Russia United States

United States Saudi Arabia

Saudi Arabia Kuwait

Kuwait Singapore

Singapore Malaysia

Malaysia UAE

UAE Germany

Germany Italy

Italy China

China UK

UK Canada

Canada Iran

Iran Thailand

Thailand South Korea

South Korea Turkey

Turkey Morocco

Morocco Costa Rica

Costa Rica Kazakhstan

Kazakhstan Philippines

Philippines Egypt

Egypt Vietnam

Vietnam Oman

Oman Australia

Australia Qatar

Qatar Portugal

Portugal Mexico

Mexico Brazil

Brazil France

France South Africa

South Africa Jordan

Jordan Spain

Spain Hong Kong

Hong Kong Netherlands

Netherlands Indonesia

Indonesia Taiwan

Taiwan Nigeria

Nigeria Bangladesh

Bangladesh Iraq

Iraq Ukraine

Ukraine Poland

Poland Romania

Romania Cyprus

Cyprus Angola

Angola Colombia

Colombia Norway

Norway Chile

Chile Tobago

Tobago Greece

Greece Czechia

Czechia Belgium

Belgium Sri Lanka

Sri Lanka Myanmar

Myanmar Venezuela

Venezuela